HF Vibrating Needles

HF Vibrating Needles

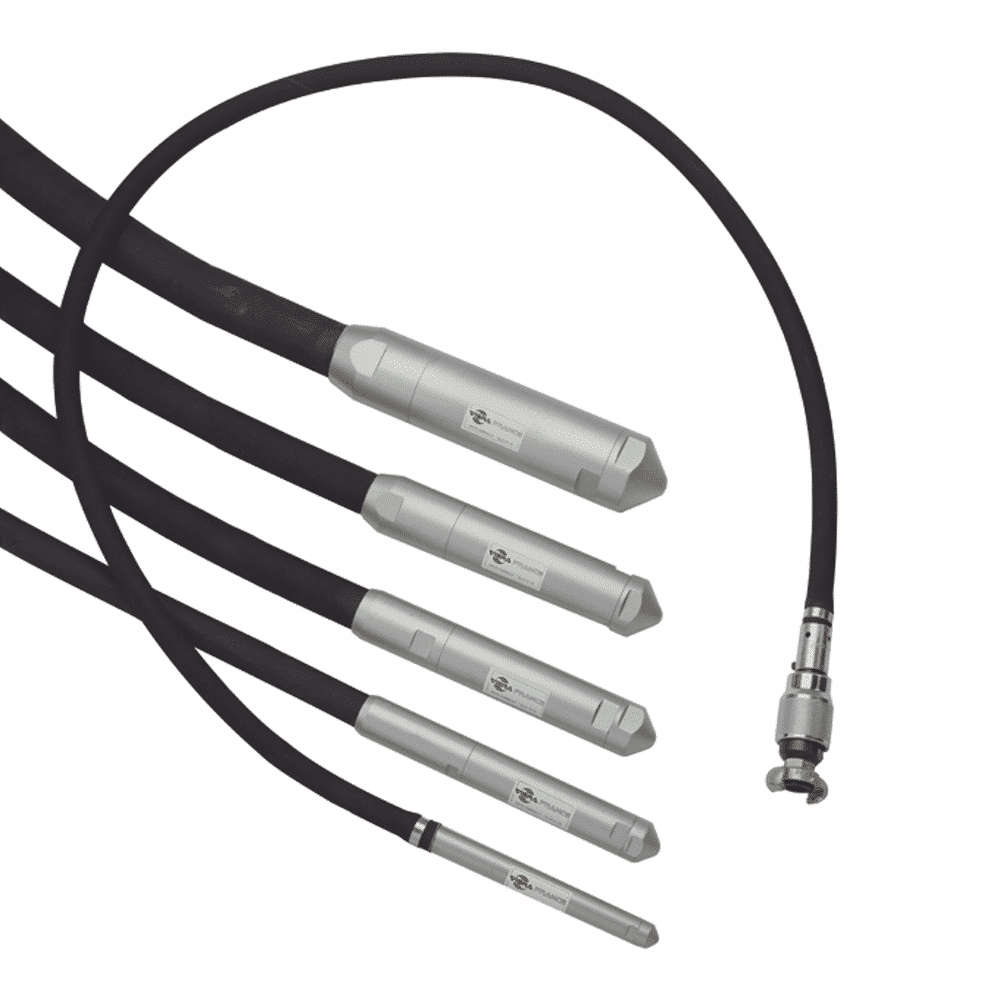

Our high-frequency vibratory needles are designed for intensive concrete compaction applications requiring a high level of performance. They are suitable for all types of construction on building sites and in prefabrication plants.

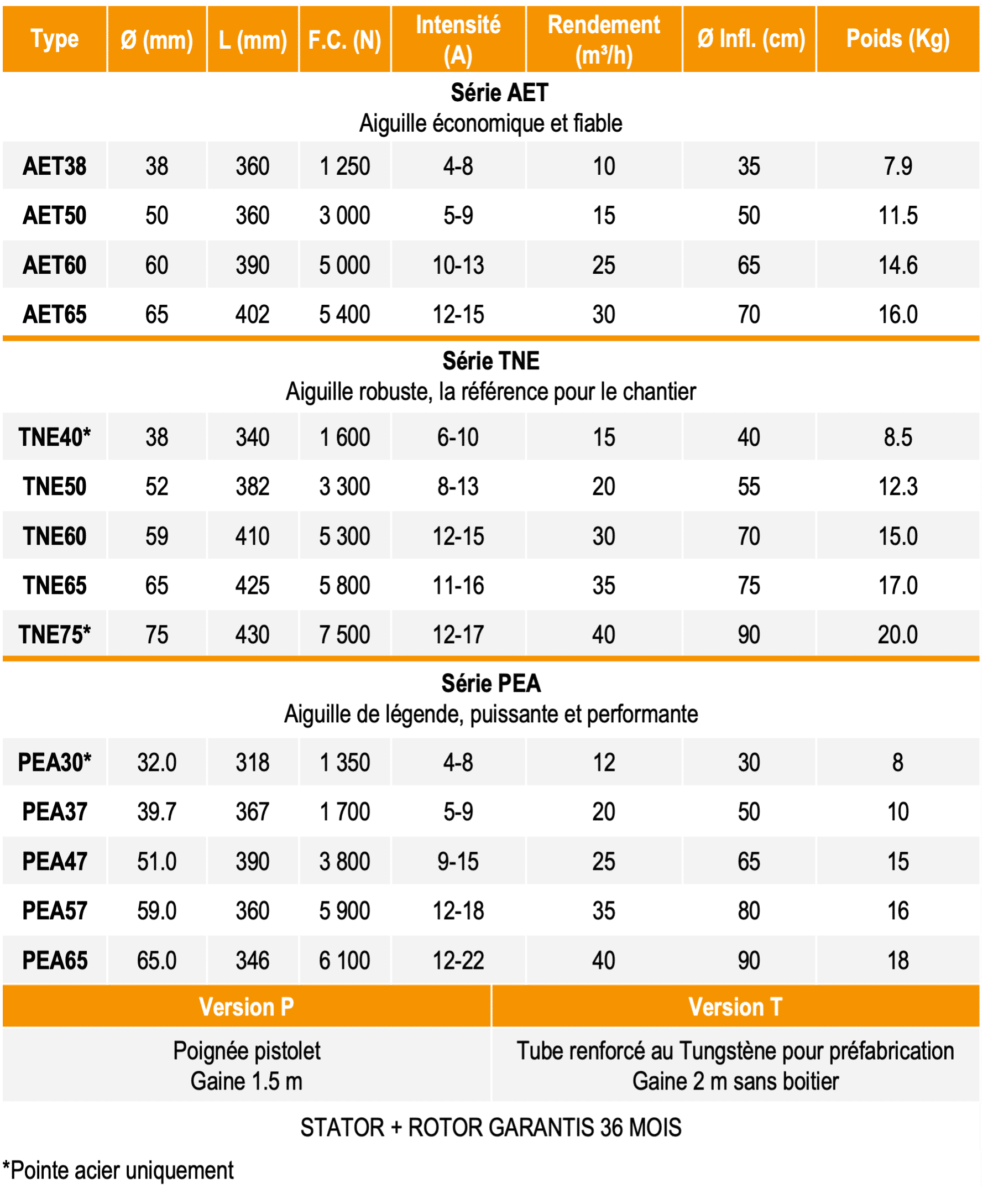

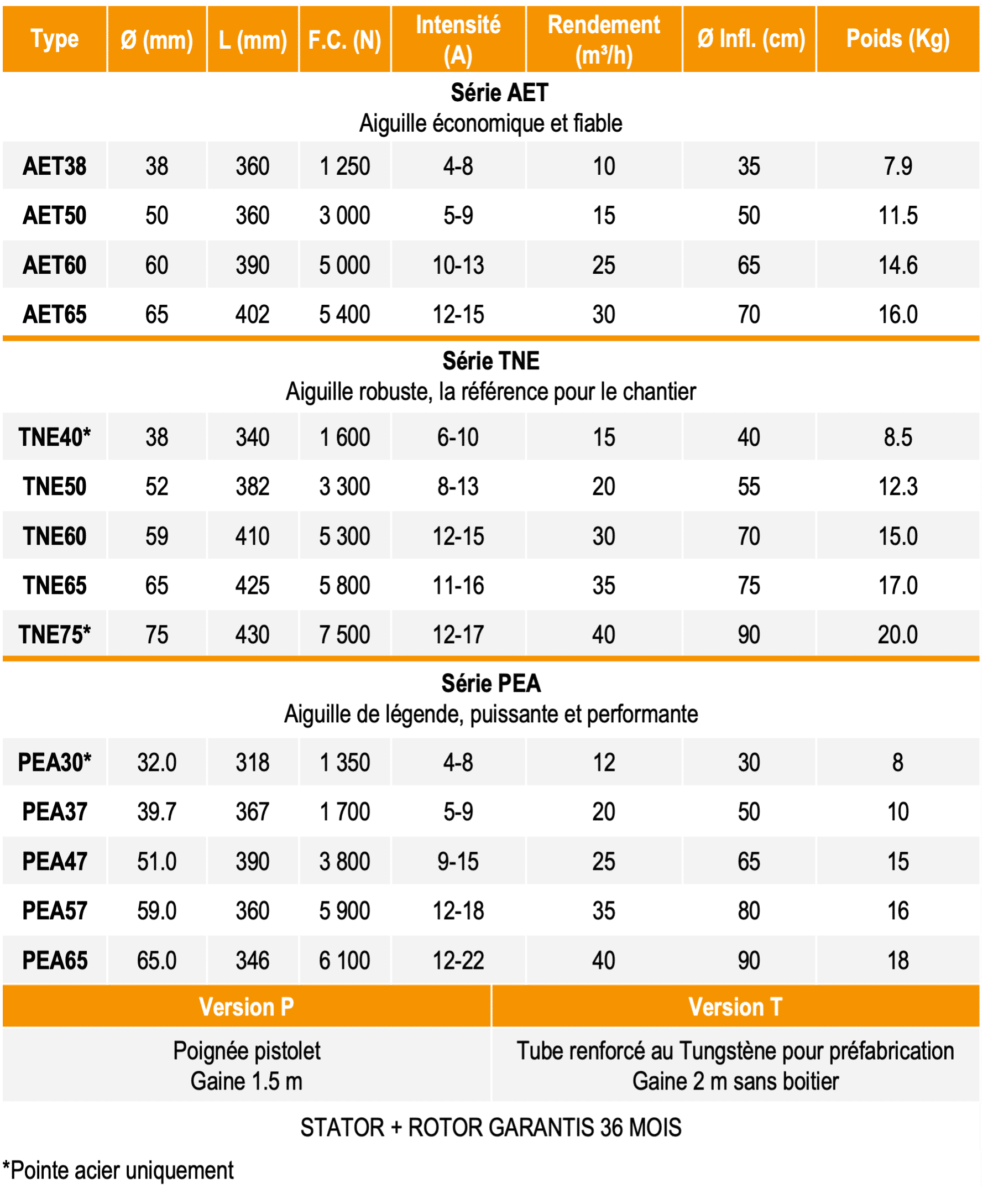

We offer 3 types of HF vibratory needles: the AET series, which is standard, the TNE series, with thermal protection, and the PEA series, with double thermal protection. Highlights :

- AET Series – Economical and reliable

- TNE Series – Robust, thermally protected and attractively priced, this is the benchmark for the construction site!

- PEA Series – Powerful, high-performance and with dual thermal protection, a legendary needle!

| Applications | |

|---|---|

| Sector | |

| Energy | Electric |

- High frequency 42 V – 200 Hz – 12,000 rpm

- Standard installation with 5-metre sheath and 10-metre cable with CEE plug

- AET series version: ABS enclosure and BREMAS switch

- TNE and PEA series: NYLON housing and MARQUARDT switch

- Supplied with steel tip as standard

- Tungsten-reinforced tube for PEA series, suitable for prefabrication draw-in needles

High-frequency concrete vibrators operate at 42 V / 200 Hz with single-phase 230 V / 50 Hz and three-phase 400 V / 50 Hz electrical converters, battery power packs or thermal generators.

High-quality components such as heavy-duty ball bearings and motor components guarantee long service life.

In the Vibra France workshops, we also make custom needle assemblies, adapting sheath and cable lengths to your needs!

Contact us directly for the following inquiries:

Vulkollan (rubber) tip instead of steel tip – Long sheath lengths up to 15 m – Long cable lengths up to 25 m

For TNE and PEA series: add a 0.70 m, 1 m or longer rigid rod.

In the PEA series, Vibra France also offers a high-frequency vibrating needle with pistol grip for prefabrication applications.

An HF electric needle must be powered by a frequency converterunless it is integrated into the device: this is the case for our HF vibrating needles with integrated converter.

Depending on the energy source available on site, a pneumatic vibrating needle or a flexible vibration unit can also be adapted!

- High frequency 42 V – 200 Hz – 12,000 rpm

- Standard installation with 5-metre sheath and 10-metre cable with CEE plug

- AET series version: ABS enclosure and BREMAS switch

- TNE and PEA series: NYLON housing and MARQUARDT switch

- Supplied with steel tip as standard

- Tungsten-reinforced tube for PEA series, suitable for prefabrication draw-in needles

High-frequency concrete vibrators operate at 42 V / 200 Hz with single-phase 230 V / 50 Hz and three-phase 400 V / 50 Hz electrical converters, battery power packs or thermal generators.

High-quality components such as heavy-duty ball bearings and motor components guarantee long service life.

In the Vibra France workshops, we also make custom needle assemblies, adapting sheath and cable lengths to your needs!

Contact us directly for the following inquiries:

Vulkollan (rubber) tip instead of steel tip – Long sheath lengths up to 15 m – Long cable lengths up to 25 m

For TNE and PEA series: add a 0.70 m, 1 m or longer rigid rod.

In the PEA series, Vibra France also offers a high-frequency vibrating needle with pistol grip for prefabrication applications.

An HF electric needle must be powered by a frequency converterunless it is integrated into the device: this is the case for our HF vibrating needles with integrated converter.

Depending on the energy source available on site, a pneumatic vibrating needle or a flexible vibration unit can also be adapted!

CE certificate

How to choose a vibrating needle

What is the purpose of a vibrating needle?

Vibrating needles are devices designed to vibrate concrete. This is an essential step in the construction process, as it helps to compact the aggregates and expel air bubbles. Vibration also ensures that molds and formwork are properly filled, and that reinforcement is embedded. The desired result? High-quality facing and optimal mechanical resistance!

In contrast to external concrete vibrators, vibrating needles use an internal vibration technique. Plunged directly into the fresh concrete, they consist of a cylinder vibrated by the rotation of an eccentric mass inside the needle. This vibratory behavior expels the air contained in the concrete, making it more compact and homogeneous.

What type of vibrating needle should I choose?

When choosing a vibrating needle, the first thing to consider is the energy source available on site:

- Pneumatic energy

Use a AIR series pneumatic vibrating needle. It will be powered by a 6-bar air flow supplied by a compressor.

- Electrical energy

Use an AET, TNE or PEA series HF vibrating needle, depending on your needs and resources. A frequency converter will be required to power the needle’s built-in electric motor, unless the motor is integrated into the device. This is the case with the EBA series HF vibrating needle-integrated converter, which connects directly to the 230 V single-phase mains supply.

- Battery-powered electrical energy

We also offer our customers HF electric vibratory needles with pistolet handle, compatible with HILTI and WACKER battery-powered devices. The lengths of the rubber sheath and the electric cable are adapted to this type of use.

- Mechanical energy

Use a vibrating needle in combination with a flexible unit vibration type RABBIT. The latter can be powered by an internal combustion engine or an electric motor.

How to select the most suitable vibrating needle?

The power and diameter of the vibrating needle depend on the mass to be vibrated. Note that the needle’s diameter in mm is equal to its action diameter in cm: a needle with a diameter of 50 mm will therefore have an action diameter of 50 cm.

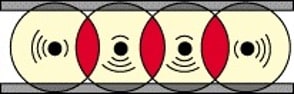

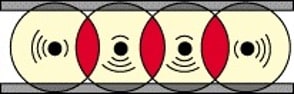

To optimize performance, the largest possible diameter is generally chosen, depending on the reinforcement. The vibrating needle must neither touch nor spread the reinforcement. Finally, it is important to ensure that the zones of action overlap correctly, so as to ensure that the entire concrete is vibrated, see below:

Overlap between action zones to leave no unvibrated space.

How to use a vibrating needle properly

The concrete must be vibrated as soon as it is placed, which is why the vibrating needle must be plunged in quickly, then raised slowly. The hole in the fresh concrete should close when the internal vibrator is withdrawn.

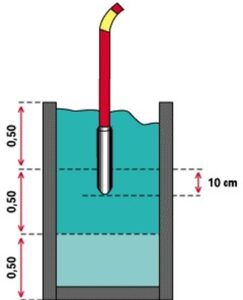

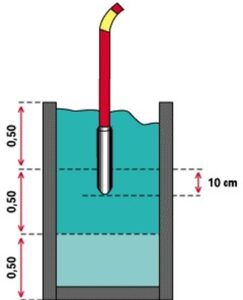

For vertical elements (walls, columns, etc.), vibration should be carried out in 50 to 60 cm layers, with the vibrator penetrating 10 to 15 cm into the previous layer of concrete.

10 cm of vibrator penetration into the previous pour.

In the case of a reservation in a wall (window opening…), it is advisable to vibrate in 50 cm layers, on one side only, until the concrete appears on the other side. This avoids the creation of an air pocket and ensures that the lower part is properly filled.

Vibration should be stopped as soon as the concrete no longer settles; the release of air bubbles ceases; and laitance begins to appear on the surface, becoming shiny.

How to select the most suitable vibrating needle?

The power and diameter of the vibrating needle depend on the mass to be vibrated. Note that the needle’s diameter in mm is equal to its action diameter in cm: a needle with a diameter of 50 mm will therefore have an action diameter of 50 cm.

To optimize performance, the largest possible diameter is generally chosen, depending on the reinforcement. The vibrating needle must neither touch nor spread the reinforcement. Finally, it is important to ensure that the zones of action overlap correctly, so as to ensure vibration of the entire concrete mass, see below:

Overlap between action zones to leave no unvibrated space.

How to use a vibrating needle properly

The concrete must be vibrated as soon as it is placed, which is why the vibrating needle must be plunged in quickly, then raised slowly. The hole in the fresh concrete should close when the internal vibrator is withdrawn.

For vertical elements (walls, columns, etc.), vibration should be carried out in 50 to 60 cm layers, with the vibrator penetrating 10 to 15 cm into the previous layer of concrete.

10 cm of vibrator penetration into the previous pour.

In the case of a reservation in a wall (window opening…), it is advisable to vibrate in 50 cm layers, on one side only, until the concrete appears on the other side. This avoids the creation of an air pocket and ensures that the lower part is properly filled.

Vibration should be stopped as soon as the concrete no longer settles; the release of air bubbles ceases; and laitance begins to appear on the surface, becoming shiny.

What are the precautions for use?

- Never bring the vibrating needle into direct contact with the formwork or reinforcement.

- To avoid overheating, do not vibrate the electric vibrating needle outside the concrete.

- It is essential to clean the vibrating needle after use to avoid any accumulation of dry concrete on the tool.

- Before storage, lubricate the pneumatic vibratory needle with a thimbleful of anti-icing oil into the hose and running it for a few seconds. Then hang it up, hose tap down, to remove any water.

- For EBA and RABBIT series vibrating needles connected directly to the mains, ensure that the power supply is protected by a 30 mA earth leakage circuit breaker and a ground wire, except for models with double-insulated motors.

Related products

Single-phase electronic converters

Single-phase converters

Three-phase electronic converters

Three-phase converters

Flexible Vibration Unit

HF vibrating needles Integrated converter

Pneumatic vibrating needles

HF Vibrating Needle Gun Handle